Advanced solutions for odor elimination

Industrial odour neutralisers: sustainable solutions against odour pollution

The impact of odour pollution on populated areas affects quality of life, and public perception of the issue can lead to complaints and fines if it is not properly controlled.

Proper odour management is a priority for many companies committed to sustainability and regulatory compliance.

What is odour pollution?

Odour pollution occurs when the molecules responsible for smells are dispersed into the air in perceptible concentrations for humans. These emissions can come from industrial processes, wastewater treatment, composting, waste handling, or the storage of organic materials.

In addition to causing nuisance to nearby residents, unpleasant odours may indicate a lack of control in biological or chemical processes, and can even affect a company’s corporate image in the eyes of local authorities and communities.

How do industrial odour neutralisers work?

Unlike air fresheners or perfumes, odour neutralisers do not mask unpleasant compounds but act directly on them. Biopulcher products use processes of absorption, adsorption, and chemical reaction through which they transform malodorous molecules into neutral or non-volatile compounds.

This technology enables genuine and long-lasting neutralisation, even in industrial environments with a high odour load.

Sustainable solutions versus traditional methods

Traditional methods based on fragrances or chemical products often displace the problem rather than solve it. In contrast, the neutralisers developed by Biopulcher are formulated with biodegradable and non-toxic ingredients that are safe for people, animals, and the environment.

Their action is effective even in large spaces thanks to nebulisation, micronisation, or controlled evaporation systems, which evenly distribute the neutralising agent throughout the air.

Applications across different sectors

Industrial odour neutralisers can be applied in a wide range of environments:

- Wastewater treatment plants and pumping stations: control of gases from hydrogen sulphide and organic matter.

- Landfills and composting facilities: neutralisation of odours produced by waste decomposition.

- Food industry: elimination of odours in processing and storage areas.

- Urban sanitation: application in sewer networks and retention tanks.

- Waste transport and handling: reduction of odour impact in containers and trucks.

In all these cases, Biopulcher products adapt to each facility through programmable systems that optimise consumption and ensure consistent results.

Commitment to sustainability

Biopulcher’s philosophy is based on developing biotechnological solutions that protect the environment and improve harmony between industry and community. Industrial odour neutralisers represent a step forward towards more efficient, sustainable, and responsible environmental management.

Odour pollution is a challenge that demands real solutions. Biopulcher’s industrial odour neutralisers provide a sustainable, safe, and effective alternative to reduce environmental impact and improve public perception of industrial facilities.

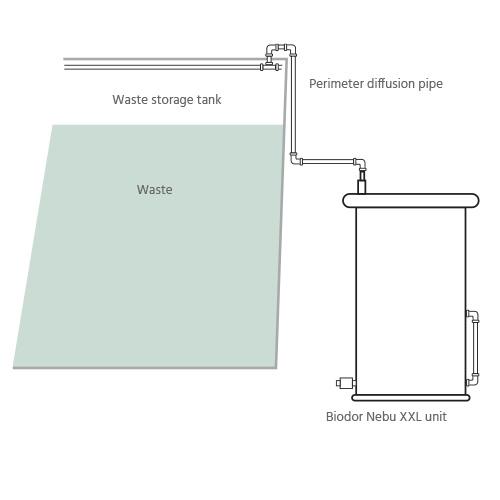

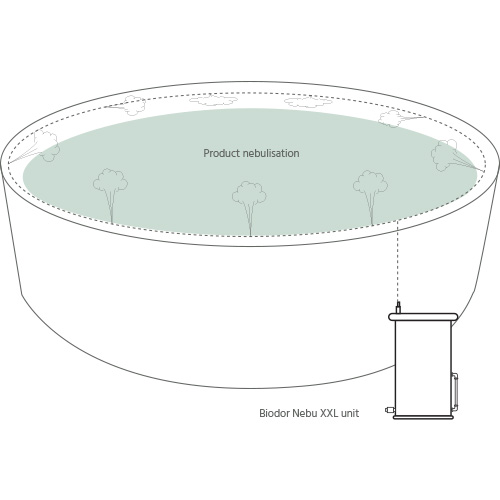

Example of an installation

Installation of a Biodor Nebu XXL unit in a waste storage tank containing food processing residues.

Application technology for odour elimination

Our added value lies in providing a comprehensive service where product quality is complemented by the most suitable application technology for each environment. It is not just about supplying a neutraliser but about designing a complete solution that ensures measurable and sustainable long-term results.

We offer different application systems that allow the treatment to be adapted to the specific conditions of each facility:

- Programmable nebulisation: automatic equipment that generates dry vapour microparticles, ideal for large or open areas.

- Micronisation and fine spraying: perfect for indoor environments or localised areas where controlled dispersion is required.

- High pressure systems and fog cannons: designed for outdoor applications or large scale industrial processes.

- Stainless steel gel holders: designed for constant and even evaporation, optimising the product’s duration and effectiveness.

This combination of sustainable neutralisers and applied technology enables us to act precisely on the odour source, minimising product consumption and avoiding residual emissions.

At Biopulcher we don’t just sell a product, we implement a complete technical solution tailored to the real needs of each client and each production process.

Example of equipment

Biodor Nebu XXL – Micronisation, dry vapour

Designed and manufactured by Biopulcher, Biodor Nebu XXL operates at low pressure using the Venturi effect to generate dry vapour microparticles. These neutralising and odour-inhibiting microparticles disperse into the air and eliminate unpleasant smells gas by gas. The unit can work with both aqueous and oily products, delivering excellent results with very low product consumption. It includes an integrated programmer that allows time slots and diffusion sequences to be set for optimal performance and efficiency. In addition, this unit is highly reliable and requires very little maintenance.

Biodor Control L - (BCL)

Biopulcher BCL is a broad-spectrum odour neutraliser designed to treat sludge from wastewater treatment plants, leachate, industrial processes, containers, septic tanks, and synthetic or mineral oils, among others.

The product comes as a concentrated water-based solution that is diluted before application. It is a highly powerful and long-lasting odour neutraliser.

The active agents in Biopulcher BCL target ammonia, hydrogen sulphide, putrescine, indole, and skatole molecules, among others.

It can be sprayed on any surface or nebulised into the air.

This product is safe for people and the environment and is backed by the following certifications:

- Biodegradability certificate

- No ocular toxicity

- No dermal toxicity

- Phytotoxicity

Available formats: 1000L, 200L, 20L, 5L