Advanced solutions for odor elimination

Olive residue treatment pits and ponds. Deodorisation and odour control system for olive waste.

Bad odours in the olive industry

In the table olive industry, one of the main environmental challenges is controlling odours emitted by liquid waste generated throughout the process. This waste – lye, brine and guiso liquor – contains organic compounds and salts that, when degraded or fermented under unsuitable conditions, release unpleasant gases such as hydrogen sulphide, volatile fatty acids and volatile organic compounds.

- Lye (also known as debittering solution) is an alkaline sodium hydroxide (NaOH) solution used at the beginning of the process to remove the olive’s natural bitterness (oleuropein). When it reacts with the pulp, it carries off organic substances that later become a source of odour if not properly controlled.

- Brine is water with salt (NaCl) used during fermentation and preservation. Over time, microorganisms convert components of the liquid into lactic, acetic and other acids, which also contribute to odour formation.

- Guiso liquor is the liquid in which olives are kept during preservation, rich in salts, acids and organic matter. When referred to as “guiso wastewater” or “spent liquor”, it denotes the final waste stream with a high odour potential.

Main odour issues in evaporation pits

- Anaerobic fermentation in deep layers

When the liquid depth is high, oxygenation is limited. Anaerobic bacteria degrade organic matter, generating hydrogen sulphide (H₂S), mercaptans, ammonia and volatile fatty acids. These are the main odorous gases. - Evaporation of volatile organic compounds (VOCs)

Although the liquid evaporates, the dissolved volatile compounds also pass into the gas phase and escape into the atmosphere. - Thermal stratification and lack of renewal

The liquid column can become stratified, with upper layers more oxygenated and lower layers remaining anaerobic and stagnant. - High concentration of residual organic load

As the liquid becomes more concentrated, the organic residues also concentrate, which can increase odour generation if the final concentrated waste stage is not properly managed.

Odour neutralisation

Odour neutralisation is a highly effective solution in the environmental management of odours generated during olive processing. It reduces the negative impact of odours on the surroundings and improves the quality of life of nearby communities.

At Biopulcher, we have developed an efficient deodorisation system for pits and ponds. This system is designed to eliminate unpleasant odours from wastewater produced during table olive processing and in meat industries, among other processes.

Our approach combines the use of the Biodor Control L (BCL) product with the Biodor Nebu XXL nebulisation equipment.

Solutions for odour control and neutralisation in pits

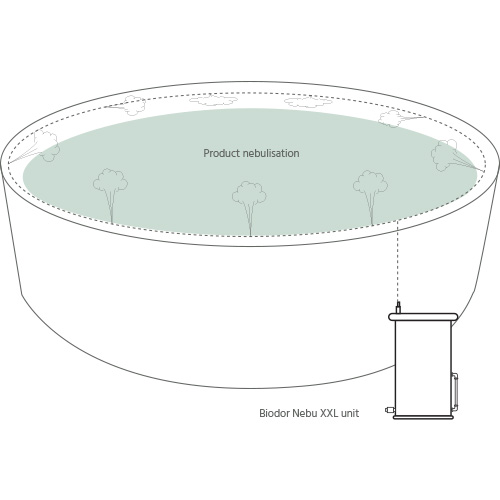

Effective odour control in evaporation ponds requires acting directly on the air phase, where volatile compounds responsible for unpleasant smells are released. In this regard, Biopulcher offers a comprehensive solution based on its Biodor Nebu XXL technology, specifically designed for the treatment of large areas and open environments.

Biodor Nebu XXL is a dry vapour nebulisation system that disperses microparticles of neutralising agents directly over the surface of the pits or ponds. These microparticles react with airborne odorous molecules such as hydrogen sulphide, mercaptans and volatile fatty acids, neutralising them instantly and preventing their dispersion into the atmosphere.

Unlike conventional spraying systems, Biodor Nebu XXL allows for homogeneous and controlled diffusion, adjusting the flow rate and nebulisation frequency according to the odour load or environmental conditions (wind, temperature, waste concentration).

Regular application of this system significantly reduces the odour impact on the surrounding area, improves the environmental perception of the facility and contributes to compliance with emission and environmental welfare regulations.

What do we achieve with this?

Main objectives

- Significantly reduce the perception of unpleasant odours.

- Improve the company’s reputation and image within the community.

- Minimise odour-related discomfort for both employees and nearby residents.

- Prevent potential complaints or legal claims.

With our solutions, we aim to create more pleasant and comfortable environments for everyone at a truly affordable cost for businesses.

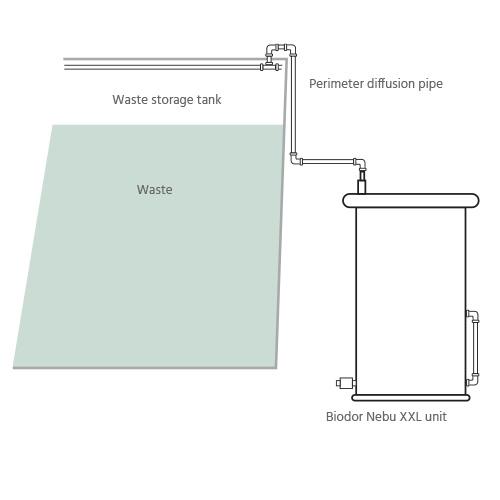

Installation layout

Equipment

Biodor Nebu XXL

Biodor Nebu XXL Nebulisation Unit, featuring a pressurisable cylindrical tank made of PPH, with a diameter of 500 mm and a height of 900 mm. This machine is low-consumption, does not interfere with the temperature or humidity of the pond, and does not affect any analytical results.

The tank is equipped with an adjustable safety valve that acts as a release mechanism in case of overpressure. Inside, it contains 18 nebulising nozzles, expandable to 36 if higher flow rates are required. The sloped bottom ensures complete drainage, with an outlet tap-valve. The tank’s product storage capacity is 60 litres.

Nebulisation times and intervals are adjustable, using a programmable timer that activates the pneumatic solenoid valve from the electrical control panel, which includes a start/stop switch built into the unit.

Installation example

Evaporation pit at Goya Spain

Biodor Nebu XXL

Entry of the multilayer pipe into the interior of the pit

Installation detail, inner perimeter of the pit

Pit with cover

Pipe inlet to the pit

Biodor Nebu XXL

Our product Biodor Control L - BCL

Biodor Control L - (BCL)

Biopulcher BCL is a broad-spectrum odour neutraliser designed to treat sludge from wastewater treatment plants, leachate, industrial processes, containers, septic tanks, and synthetic or mineral oils, among others.

The product is supplied as a water-based concentrate and must be diluted before use. It is a very powerful and long-lasting odour neutraliser.

The active agents in Biopulcher BCL target ammonia, hydrogen sulphide, putrescine, indole and skatole molecules, among others.

It can be sprayed on any surface or nebulised into the air.

This product is safe for both people and the environment, and holds the following certifications:

- Biodegradability certificate

- Ocular non-toxicity

- Dermal non-toxicity

- Phytotoxicity

Available formats: 1000L, 200L, 20L, 5L

Eliminate unpleasant odours effectively

Unpleasant odours are not only a nuisance but also a challenge for sustainability and community acceptance.

Our innovative solution not only eliminates odours effectively but also promotes a cleaner and healthier environment for everyone.

Why choose Biopulcher?

- Proven Results: Our system has been extensively tested and combines the power of Biopulcher BCL with the advanced nebulisation technology of the Biodor Nebu XXL to ensure effective odour elimination.

- Sustainability: We are committed to providing solutions that are not only effective but also environmentally friendly, helping to enhance your company’s image within the community and among regulatory authorities.

- Improved Quality of Life: By reducing odour-related discomfort, you not only improve the working environment for your employees but also strengthen relationships with neighbours and the local community.

Don’t let unpleasant odours affect your business and reputation.

Discover how our solutions can transform your environment, making it more pleasant and professional. Contact us now and take the first step towards a cleaner, fresher atmosphere!