Advanced solutions for odour elimination

Sustainable solutions for odour elimination in composting plants

Composting and organic waste treatment plants inevitably generate odour pollution as a result of organic matter decomposition.

During fermentation and degradation processes, compounds such as hydrogen sulphide (H₂S), ammonia (NH₃), putrescine, cadaverine, and volatile fatty acids are released, causing strong odours that can affect the surrounding environment and disturb nearby populations.

To reduce these emissions, Biopulcher has developed a comprehensive odour neutralisation and elimination treatment based on the application of biodegradable, sustainable, and highly effective neutralisers.

The product used, Biodor Control L (BCL), holds biodegradability, non-ocular toxicity, non-dermal toxicity, and phytotoxicity certifications, ensuring safe use and full environmental compatibility.

Odour control measures implemented

- Compost pile deodorisation

The diluted Biodor Control L neutralising product is applied over the compost piles using a high-pressure nebulisation cannon. This equipment generates a fine mist capable of covering large surfaces and neutralising volatile compounds responsible for unpleasant odours. The treatment is carried out periodically, adjusting the frequency according to weather conditions and waste load. - Leachate pond treatment

A high-pressure system with nebulisation nozzles and perimeter fans has been installed in the leachate pond, allowing the product to be directed towards areas with the highest emission levels. This system can be divided into sectors depending on wind direction and odour concentration, optimising both product consumption and process efficiency. - Perimeter odour containment treatment

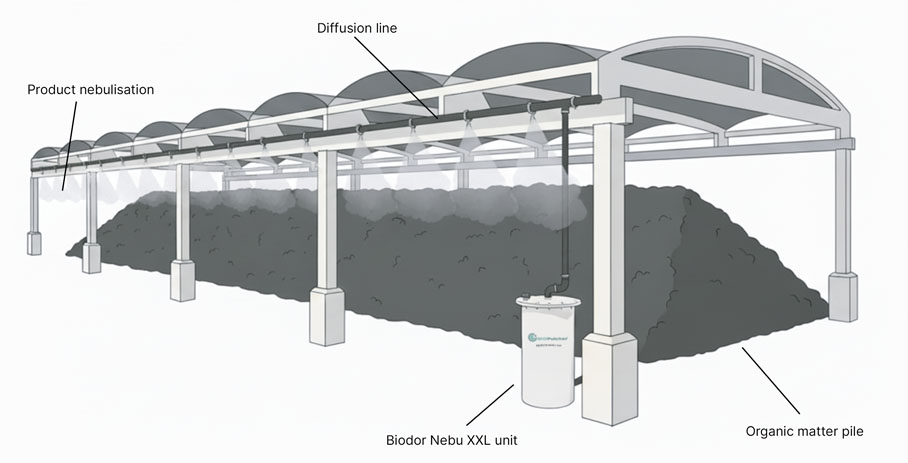

To strengthen odour removal and prevent its spread, a perimeter deodorisation barrier has been created using two Biodor Nebu-XXL units. These systems produce an ultra-fine, low-consumption mist that acts as an environmental shield, significantly reducing odour nuisance in the surrounding area.

Results

Thanks to the combination of nebulisation technologies and the use of certified odour neutralisers, the treatment has notably reduced the odours generated during the composting process and leachate management.

The use of sustainable solutions and non-toxic, biodegradable products reinforces Biopulcher’s commitment to innovation and environmental protection, delivering effective odour elimination in composting plants and other high-demand environments.

Example of installation

Installation of a Biodor Nebu XXL unit for the elimination of organic waste odours

Example of equipment

Biodor Nebu XXL – Micronisation, dry vapour

Designed and manufactured by Biopulcher, Biodor Nebu XXL operates at low pressure using the Venturi effect to generate dry vapour microparticles. These neutralising and odour-inhibiting microparticles disperse into the air and eliminate unpleasant smells gas by gas. The unit can work with both aqueous and oily products, delivering excellent results with very low product consumption. It includes an integrated programmer that allows time slots and diffusion sequences to be set for optimal performance and efficiency. In addition, this unit is highly reliable and requires very little maintenance.

Biodor Control L - (BCL)

Biopulcher BCL is a broad-spectrum odour neutraliser designed to treat sludge from wastewater treatment plants, leachate, industrial processes, containers, septic tanks, and synthetic or mineral oils, among others.

The product comes as a concentrated water-based solution that is diluted before application. It is a highly powerful and long-lasting odour neutraliser.

The active agents in Biopulcher BCL target ammonia, hydrogen sulphide, putrescine, indole, and skatole molecules, among others.

It can be sprayed on any surface or nebulised into the air.

This product is safe for people and the environment and is backed by the following certifications:

- Biodegradability certificate

- No ocular toxicity

- No dermal toxicity

- Phytotoxicity

Available formats: 1000L, 200L, 20L, 5L